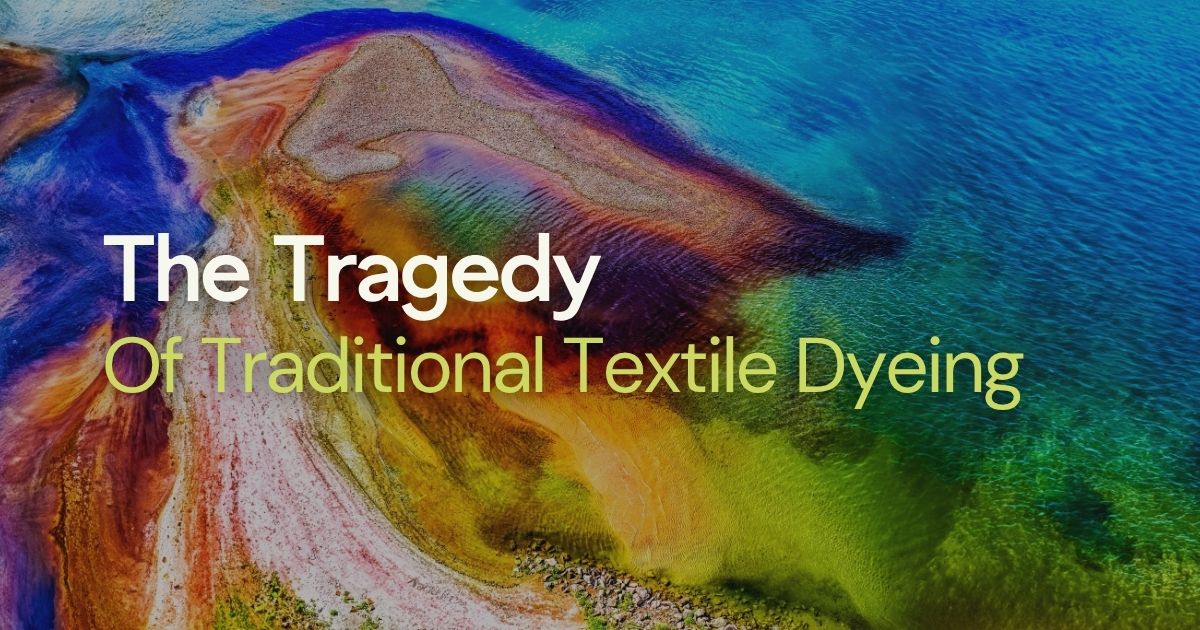

Traditional textile dyeing is one of the most polluting processes in the textile industry. It relies heavily on water, energy, and chemicals to fix colour onto the fabric, often coming with environmental consequences. Wastewater from dyehouses is frequently discharged untreated into rivers and streams, carrying toxic dyes and heavy metals that harm the environment and potentially contaminate drinking water. The sheer scale of production, combined with outdated methods, makes traditional textile dyeing a major contributor to water pollution, carbon emissions, and chemical waste globally.

Traditional textile dyeing is one of the most polluting processes in the textile industry. It relies heavily on water, energy, and chemicals to fix colour onto the fabric, often coming with environmental consequences. Wastewater from dyehouses is frequently discharged untreated into rivers and streams, carrying toxic dyes and heavy metals that harm the environment and potentially contaminate drinking water. The sheer scale of production, combined with outdated methods, makes traditional textile dyeing a major contributor to water pollution, carbon emissions, and chemical waste globally.

Why Traditional Textile Dyeing is Not Sustainable

With traditional textile dyeing, to produce one single t-shirt, it consumes up to 2,700 litres of water. The process involves mixing water with dyes and chemicals, creating toxic wastewater that often ends up polluting rivers and ecosystems. Heating this water also demands significant energy, contributing up to 36% of a garment’s total carbon footprint.

According to the Apparel Impact Institute (2023), greenhouse gas emissions from the apparel sector rose by 7.5% between 2022 and 2023 - the first annual increase since 2019. This trend highlights how outdated dyeing practices are undermining sustainability efforts across the industry.

The Tragedy Behind Traditional Textile Dyeing

The Tragedy Behind Traditional Textile Dyeing

Despite increasing awareness from conscious consumers and industry regulations, many of these harmful practices continue to be used.

Brands, dyehouses, and textile manufacturers who remain reluctant to change could:

- Face fines up to 10% of their global revenue, particularly for misleading sustainability claims (Gardner, J., 2025).

- Risk retrofitting their outdated dyehouses, which would require significant financial investment.

- Be subject to consumer backlash over accusations of greenwashing or unethical environmental practices.

So, until brands and dyehouses overhaul their traditional textile dyeing methods, any environmental claims they make risk being nothing more than empty promises.

Time For a Better Way

For too long, traditional textile dyeing methods have gone unchecked and became a tragedy in sustainability. But with clean-tech innovations, like digital textile dyeing, sustainable textiles can be a reality. Brands, dyehouses, and textile manufacturers that invest in clean technologies will lead a sustainable future and address industry shortfalls in sustainability.

The environmental damage of traditional textile dyeing can be prevented. With the right technologies and approach, the industry can turn sustainable textiles into a reality.

Pioneering this change is Alchemie Technology – a clean-tech innovator revolutionising traditional textile dyeing. Offering near-waterless, low-carbon digital solutions for small- to large-scale brands and dyehouses through our Endeavour™ and Discovery systems.

Alchemie’s Endeavour™ and Discovery systems can dye both natural or synthetic fibres, either woven or knitted. Using high-speed nozzles to dispense nanolitre droplets of dye to ensure repeatable results of superior colour consistency and fastness. All of which enables brands and dyehouses to reduce their production times by having on-demand textile dyeing in their hands. Enabling you to avoid the high-temperature, high-liquor ratio of traditional textile dyeing methods that generate the majority of textile dyeing’s waste pollution.

Making Sustainable Textiles a Reality

The future of textile dyeing hangs in the balance. Brands that adopt clean-tech like digital dyeing stand to reduce their environmental impact dramatically while improving transparency and efficiency. By implementing clean-tech innovations, like digital textile dyeing, the industry can prove to itself that it can make sustainable textiles a reality and leave the tragedy behind.

At Alchemie, we have built solutions that change the status quo, enabling brands and dyehouses to deliver superior, repeatable dyed fabrics without sacrificing sustainability.

Cleaner, scalable solutions that are available now.

Contact us to drive your sustainable production at enquiries@alchemietechnology.com.