The global textile supply chain is undergoing a long-overdue transformation and the shift begins at Tier 2, where fabrics are dyed, finished, and prepared for manufacturing. For decades, this stage has been responsible for some of the highest levels of water use, chemical discharge, and energy consumption in the entire industry. As brands accelerate sustainability commitments and production pressures grow, the need for a cleaner, smarter, digital alternative is no longer optional, it’s urgent.

This is where Alchemie operates. Re-engineering Tier 2 with precision digital technology that dramatically reduces production costs and environmental impact while delivering consistent, premium colour on a broad range of fabrics and dye chemistries.

Rethinking How Colour Meets Fabric

Traditional dyeing is built on immersion, high liquor ratios, heavy energy use, and complex chemistry management. It’s also responsible for millions of litres of wastewater every year, much of it contaminated and difficult to treat.

Alchemie changes this model completely.

Founded in 2013, we asked: what if textile dyeing could be as precise as advanced inkjet technology? Over the past decade, that idea has evolved into a breakthrough platform featuring custom-engineered nozzles that jet 1.2 billion droplets per linear metre of fabric. Combining larger droplet sizes, high velocity, and 10-micron droplets, these nozzles deliver exceptional penetration and precision across all fibres and chemistries. Designed with medical-grade sophistication, they set a new standard for accuracy, consistency, and low-waste dyeing.

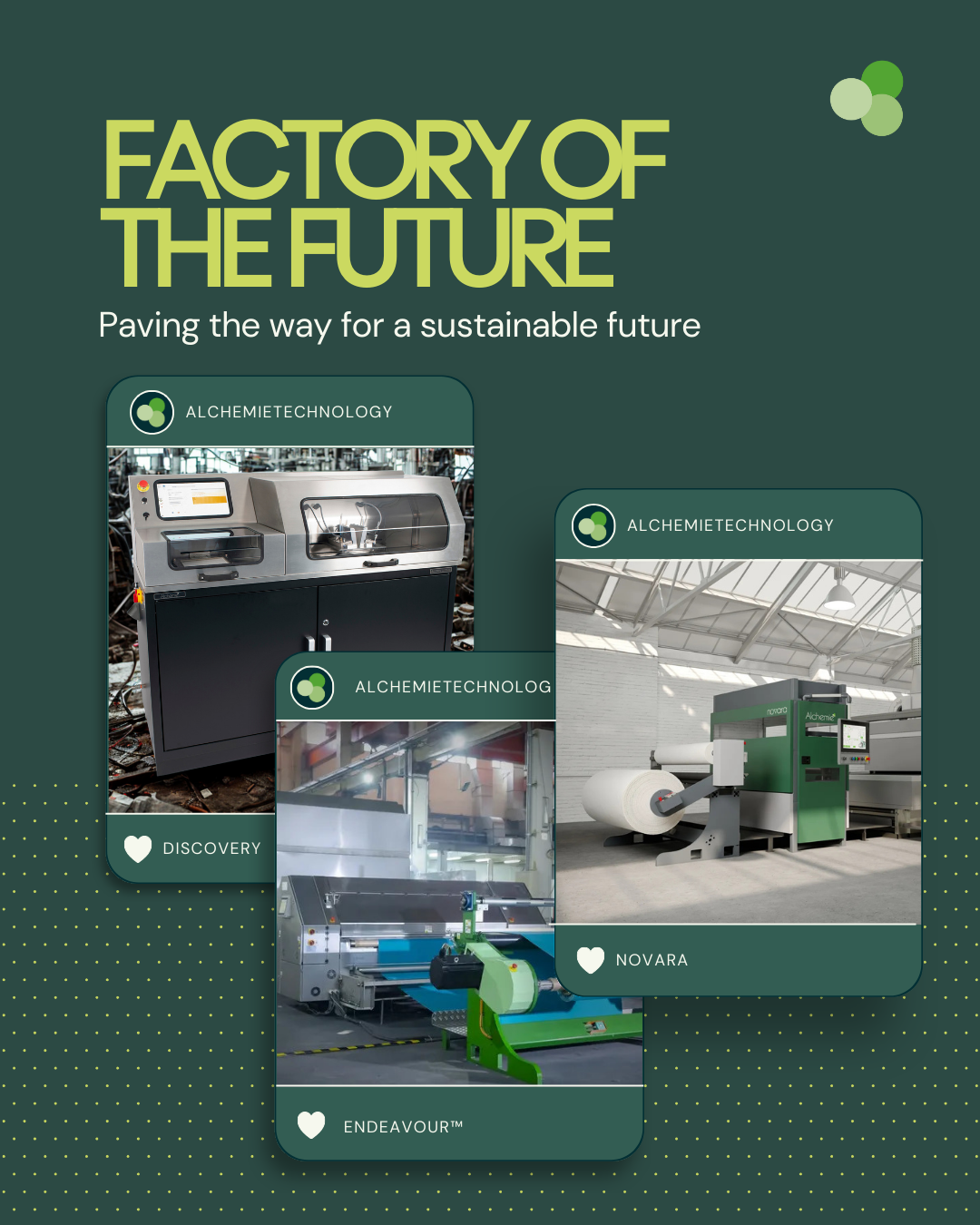

At the heart of the Factory of the Future is our digital, non-contact dyeing and finishing line, powered by three integrated systems:

- Discovery – Replicates the digital dyeing production system, Endeavour, at lab scale to generate recipe-to-production colour libraries, speed up colour-matching, and validate effects with a non-contact digital jet applicator.

- Endeavour™ – A production-scale digital textile dyeing system. It rejects traditional immersion-based bath dyeing and instead uses a non-contact, high-energy nanodroplet jetting process to apply dye directly to fabric.

- Novara™ – A precision digital finishing system, based on non-contact nozzle-jetting, that applies finishing chemistries only where needed — not saturating the entire fabric in a bath.

Together, these systems replace multiple resource-intensive steps with a clean, connected production workflow, from processing the dye recipe, all the way to fabric finishing.

Dye-Agnostic, Fabric-Agnostic, Production-Ready

Unlike niche technologies restricted to a single chemistry or fibre type, Alchemie’s platform is built for real-world manufacturing.

Supported dye classes:

- Reactive

- Disperse

- Acid

- Pigment

Supported fabric types:

- Cotton

- Polyester

- Viscose

- Lyocell

- Nylon

- Synthetic and cellulosic blends

- Elastane-containing fabrics

- Woven, knit, and non-woven substrate

This agnostic capability means manufacturers can switch to digital without compromising their existing material portfolio or their colour standards.

Tier 2 Benefits That Transform the Bottom Line

Alchemie’s technology is not only about sustainability,it delivers direct, material cost benefits that reshape OPEX for textile dyehouses.

Our digital dyeing process eliminates the water and steam heavy stages common in conventional dye houses, thereby slashing OPEX. Because Endeavour applies dye via digitally controlled 10‑micron droplets, we remove the need for large water volumes. This dramatically reduces recurring costs (water procurement, energy for heating and steam generation, chemicals usage, labour and waste disposal).

In conventional jet‑exhaust or bath dyeing systems, studies of typical Chinese textile dyeing operations have shown high resource and waste burdens, large water consumption, significant steam and energy use, and extensive wastewater disposal costs.

This is the factory of the future that doesn’t compromise on quality — or cost.

The Factory of the Future Is Already Here

The textile industry has long accepted that dyeing must be messy, wasteful, and resource heavy. But today, digital precision is proving that another path is possible, one where manufacturers cut costs, brands reduce impact, and consumers gain transparency into how their clothes are made.

By transforming the process, Alchemie is reshaping the entire foundation of textile production: cleaner processes, smarter systems, and faster, more efficient colour application at scale.

If you’re ready to move toward a digital, low-impact future, our team is here to support your transition.

To learn more or speak to our team, contact us at:

enquiries@alchemietechnology.com