As the year draws to a close, it’s the ideal moment for dyehouses and textile manufacturers to reflect on one of the most critical performance indicators in modern production: water and chemical efficiency.

Traditional dyeing has long been associated with excessive resource consumption, unpredictable outputs, and heavy wastewater loads. But with the shift toward digital dyeing, manufacturers now have access to accurate, transparent data that makes year-end analysis simpler, faster, and far more meaningful.

Digital Dyeing Makes Your Data Clear, Accurate, and Actionable

This annual review is your opportunity to understand exactly how much water you’ve saved, how your chemical usage has changed, and how digital processes have improved your environmental footprint. With Alchemie’s Endeavour™ digital dyeing technology, these numbers are no longer rough estimates. Every litre of water, every gram of chemical, and every process variable can be measured with precision, providing a clear picture of your efficiency gains throughout the entire year.

From Cost Savings to Compliance: Why the Numbers Matter

The power of this data goes beyond sustainability. Reduced water consumption results in lower operating expenses, less wastewater to manage, and improved compliance with increasingly stringent environmental regulations. Decreasing chemical usage results in fewer rejects, cleaner recipes, safer working conditions, and more consistent shades. When you quantify these improvements during your year-end review, you’re documenting measurable progress that adds real value to your business, not just to your ESG reporting.

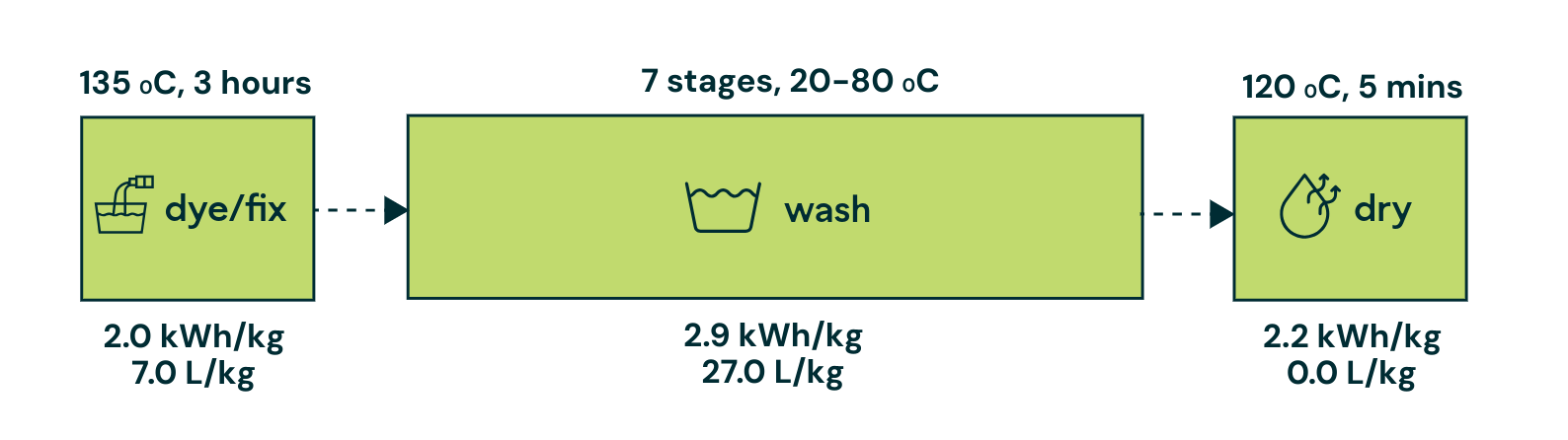

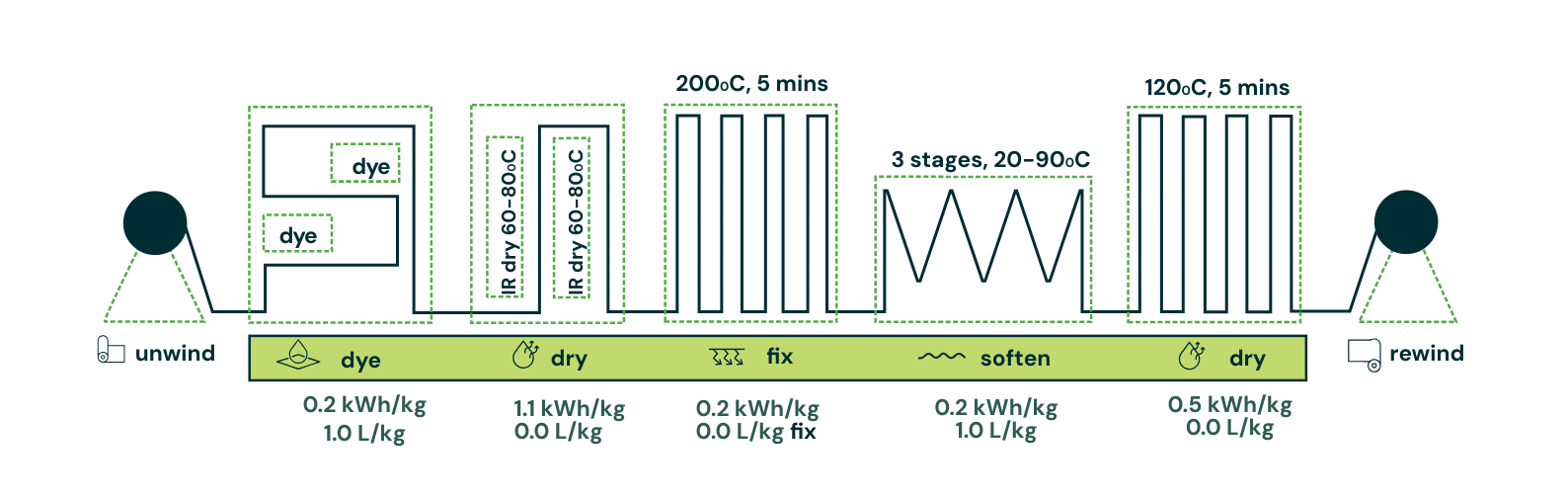

The image above illustrates the water and energy footprint of traditional textile dyeing, 34.0 L of water and 7.1 kWh of energy per kilogram of fabric. In contrast, Alchemie’s Endeavour™ digital dyeing process requires only a fraction of these resources.

2025: A Landmark Year for Clean Textile Dyeing

This year has also been significant for the global push toward clean textile dyeing, strengthening the relevance of the improvements you’re reviewing now. Around the world, stricter environmental standards and growing pressure from brands have accelerated the transition away from resource-intensive dye processes. Industry conversations throughout 2025 have consistently highlighted the urgent need for cleaner, electrically powered, low-waste dyeing systems — exactly the space where Alchemie’s non-contact digital dyeing technology stands at the forefront.

Endeavour™ Delivers Measurable, Repeatable Resource Savings

Endeavour™ has proven throughout the year that large-scale resource savings aren’t just possible, they’re repeatable and measurable. With up to 95% less wastewater, 30% fewer chemicals, and no requirement for large dye baths or rinses, digital dyeing offers a radically different approach compared to traditional jet, winch, or continuous dye lines. These results become even more powerful when captured and reviewed at year's end, forming the foundation of your sustainability strategy for the coming year.

Year-End Review is More Than Reporting

As you analyse your performance, consider how the data gathered this year can guide your next steps. Your savings reveal where you’ve improved and where further optimisation is possible. They also help you set realistic, ambitious goals for 2026, whether that means expanding digital dyeing capacity, replacing older machines, or refining your production planning to maximise efficiency with Alchemie’s technology.

Year-end is more than a reporting exercise. It’s a chance to recognise the real progress you’ve made, backed by real numbers, using technology designed for a cleaner textile future. If digital dyeing has helped transform your operations this year, your annual review is the moment to bring that impact into focus and to prepare for even greater advancements ahead.

Contact us to discover how our technology will change your facility for the better, discuss the savings, and we’ll take it from there! Book your meeting with us: enquiries@alchemietechnology.com